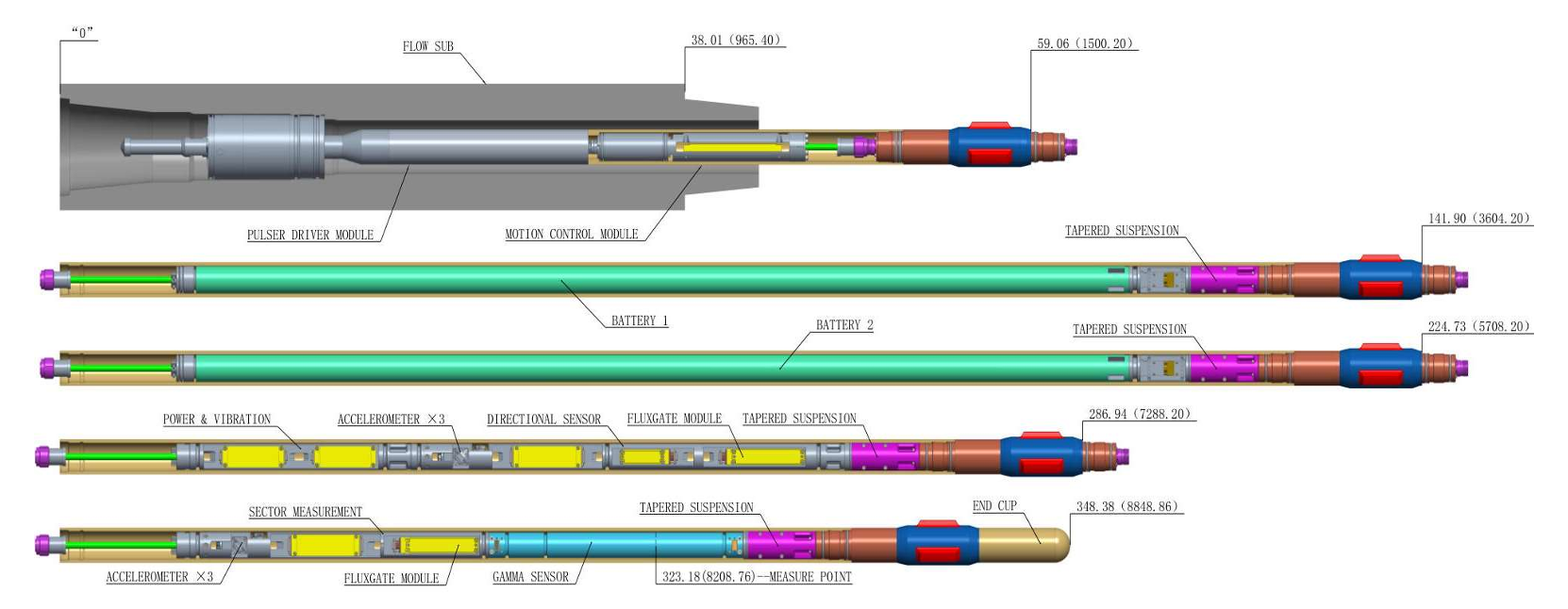

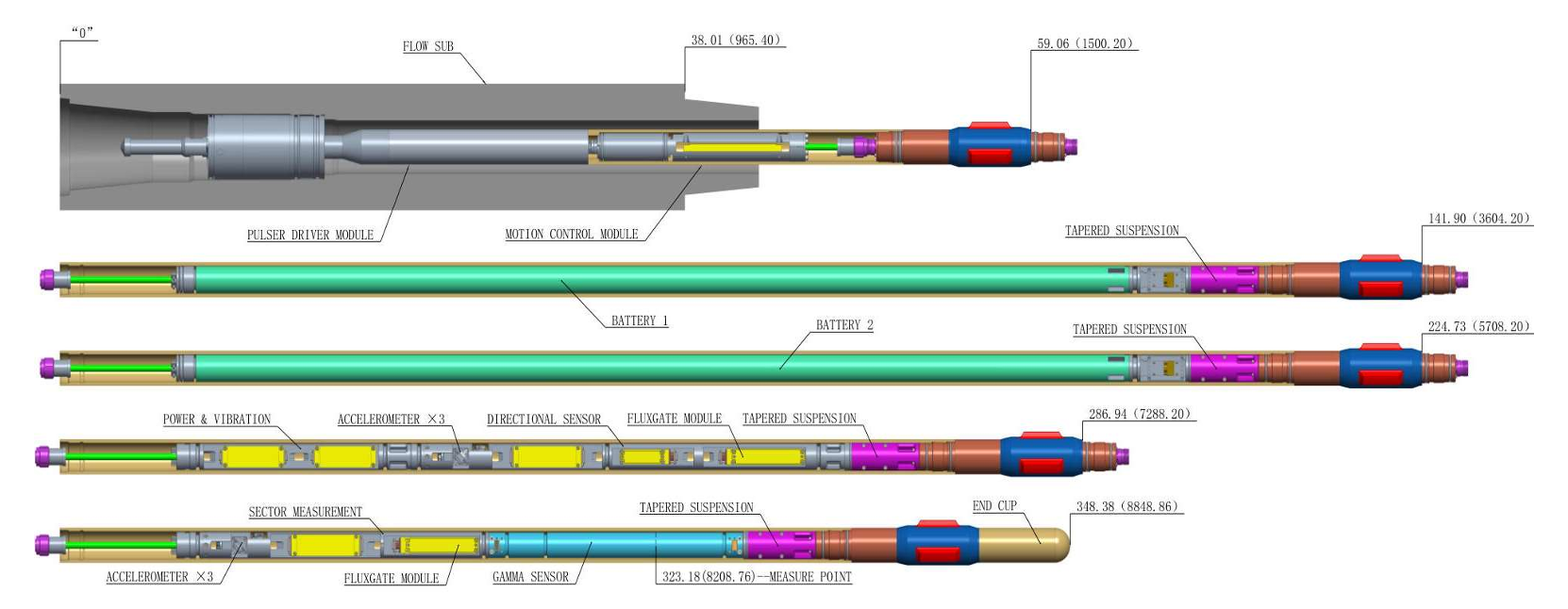

The ZTMWD-NT wireless MWD system consists of a surface decoding system and downhole tools. All

circuits in the downhole tools are manufactured using high-temperature MCM (Multi-Chip Module)

technology, ensuring excellent long-term reliability and service time in high-temperature and

high-vibration environments, with a maximum operating temperature of 150

℃

. With high-precision

compensation and calibration algorithms, the system achieves high-accuracy inclination and azimuth

measurements across the entire temperature range and supports dynamic rotary measurements, to

improve directional drilling efficiency. The system features a modular design with high-temperature

rectangular connectors, and all hardware and software are independently developed. It offers strong

scalability, allowing customization of mechanical and electrical interfaces to connect with resistivity tool,

rotary steerable systems, and near-bit tool as per customer requirements.

The driller’s display supports wireless communication, simplifying field wiring and enhancing

operational efficiency. The battery pack supports real-time monitoring of power consumption.

2. SystemFeatures

2.1. High-temperature Multi-Chip Module (MCM) Electronic System

Enhances reliability in high-temperature and high-vibration environments, improving tools

stability and sevice time.

•

•

•

Modular design with micro-rectangular connectors, reducing maintenance time.

Decreases the frequency of circuit component repairs and maintenance.

2.2. Advanced Dynamic Rotary Measurement and Directional Sensors

Supports multiple dynamic rotary measurements within a single drill string, saving

measurement time.

•

•

•

Improves trajectory control.

Reduces the risk of stuck pipe incidents.

2.3. Real-time Vibration, Shock, and Rotational Speed Monitoring

Measures, records, and analyzes downhole vibration and shock, including axial (bit bounce),

lateral, and torsional (stick-slip and whirl).

•

Provides real-time vibration severity for optimizing rotational speed and improving drilling

efficiency.

•

Issues real-time vibration alerts to adjust drilling parameters promptly.