I. How does MWD work?

The MWD system is a highly integrated complex system. Its workflow can be divided into three main steps:

1. Measurement:

Behind the drill bit, a string of precision instruments known as "downhole tools" is installed. These instruments contain various sensors used to measure two types of key information:

Engineering Parameters: Wellbore orientation (inclination angle, azimuth angle), toolface angle (used for steering), downhole temperature, downhole vibrations, torque, etc. These parameters are directly related to drilling safety and efficiency.

Geological Parameters: Formation natural gamma ray, resistivity, density, etc. These parameters help geologists determine what type of rock formation the drill bit is currently in and whether it contains oil and gas.

2. Encoding:

The data collected by the sensors are electrical signals, which need to be converted into digital signals, encoded, and packaged according to specific protocols, ready to be "sent."

3. Transmission:

This is the most magical part of MWD technology. Due to the physical barrier of the steel drill pipe and the obstruction of kilometers of rock formation, traditional cable transmission is impossible. Engineers use several ingenious "wireless" methods:

Mud Pulse (Mud Pulse): This is currently the most mainstream technology. It generates pressure wave signals by altering the flow state of the drilling fluid (mud). Specifically, a device can rapidly open and close like a shutter, or create a tiny vortex in the mud flow, thereby generating positive pulses, negative pulses, or continuous waves in the mud column. These pressure waves travel up the mud column at the speed of sound (approx. 1200-1500 m/s) to the surface, where they are detected by pressure sensors.

Electromagnetic Wave (EM): Uses the formation as a transmission medium to send signals to the surface via low-frequency electromagnetic waves. This method does not require mud circulation, but the transmission depth is greatly affected by formation resistivity.

Acoustic Wave (Acoustic): Uses the drill pipe itself as a sound channel for transmission. This is currently less commonly used.

4. Decoding & Display:

Surface equipment receives the weak pressure wave signals, then filters noise, amplifies, and decodes them, restoring them into digital data. Finally, this data is displayed on computer screens for drilling engineers and geologists in the form of curves, numbers, and 3D models, intuitively showing the wellbore trajectory and formation properties.

II. The Great Value of MWD Technology

Geosteering: Enables real-time identification of hydrocarbon zones, guiding the drill bit to navigate through the optimal reservoir, maximizing exposure to the pay zone, and significantly increasing production.

Improved Drilling Safety: Real-time monitoring of downhole torque, vibrations, etc., allows for early warning of potential incidents such as drill string damage or stuck pipe.

Optimized Drilling Efficiency: Precise control of the wellbore trajectory avoids drilling into non-target areas, saving drilling time and costs.

Acquisition of High-Quality Data: Measures the formation's original parameters before it is invaded and contaminated by drilling fluid, resulting in more authentic and reliable data.

Brief Elaboration on MWD Instruments:

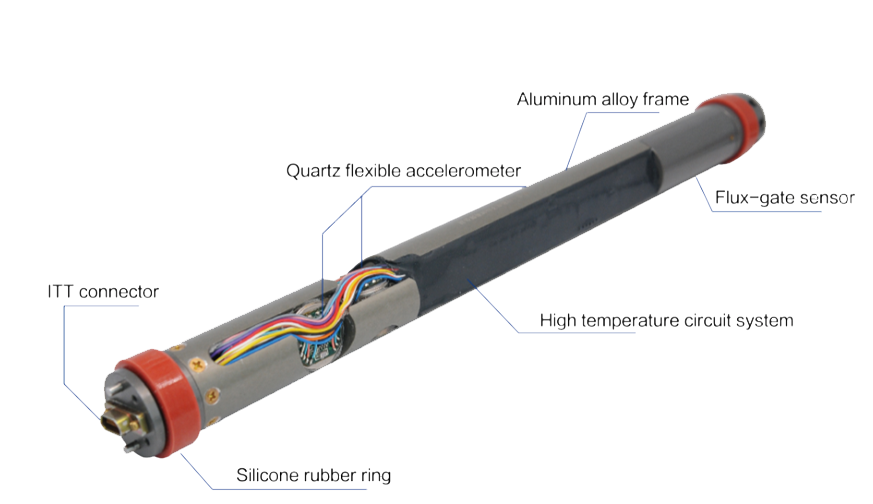

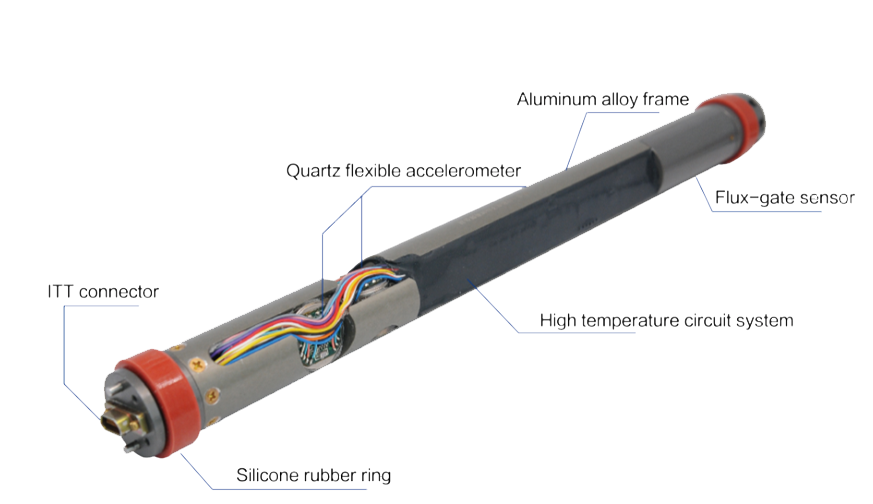

The "downhole tools" mentioned above are the core part of MWD instruments. They typically consist of one or more rugged metal cylinders (called "subs") connected between drill collars. Their main modules include:

1. Power System: Powers the entire instrument. Typically, a turbine generator (powered by mud flow) or high-performance lithium batteries are used, with the latter becoming mainstream due to their stability and long life.

2. Sensor Module:

Directional Sensors: Include triaxial accelerometers and triaxial magnetometers, acting like a "3D compass" used to precisely calculate inclination, azimuth, and toolface angle.

Gamma Sensor: Measures the natural radioactivity of the formation. Different lithologies have different radioactivity (e.g., shale is high, sandstone is low), making it a key tool for distinguishing rock layers.

3. Control System: responsible for controlling sensor sampling, data encoding, and the actuation timing of the pulse generator.

4. Pulse Generator (Telemetry Valve): The "voice box" of the MWD, one of the most technologically advanced components. It actuates the valve (a poppet or sleeve) precisely based on the encoded data to generate the corresponding mud pressure pulses.

5. Pressure Housing: All precision components are sealed within an alloy shell capable of withstanding extremely high external pressure (up to 170 MPa or more) and high temperature (175°C or above) to cope with the harsh downhole environment.

-

Above all private opinion, if you have any further questions or need additional clarifications, please feel free to left your messages. More, Qingdao ZITN Technology Co., Ltd is working on MWD instrument and directional sensors for many years, welcome you contact us more mutual understanding.