In petroleum logging, equipment often operates under extreme conditions such as high temperatures and vibrations, making a stable and reliable power supply critical for device performance. As global oil and gas resource exploration advances into deeper strata, the temperature underground rises by approximately 30°C for every 1,000 meters of depth. As a core component of high-temperature drilling equipment, the high-temperature reliability of power supply products directly impacts the performance of drilling systems. From the stable operation of downhole motors to the accurate transmission of signals, every aspect relies on power supplies with stable performance and high-temperature resistance.

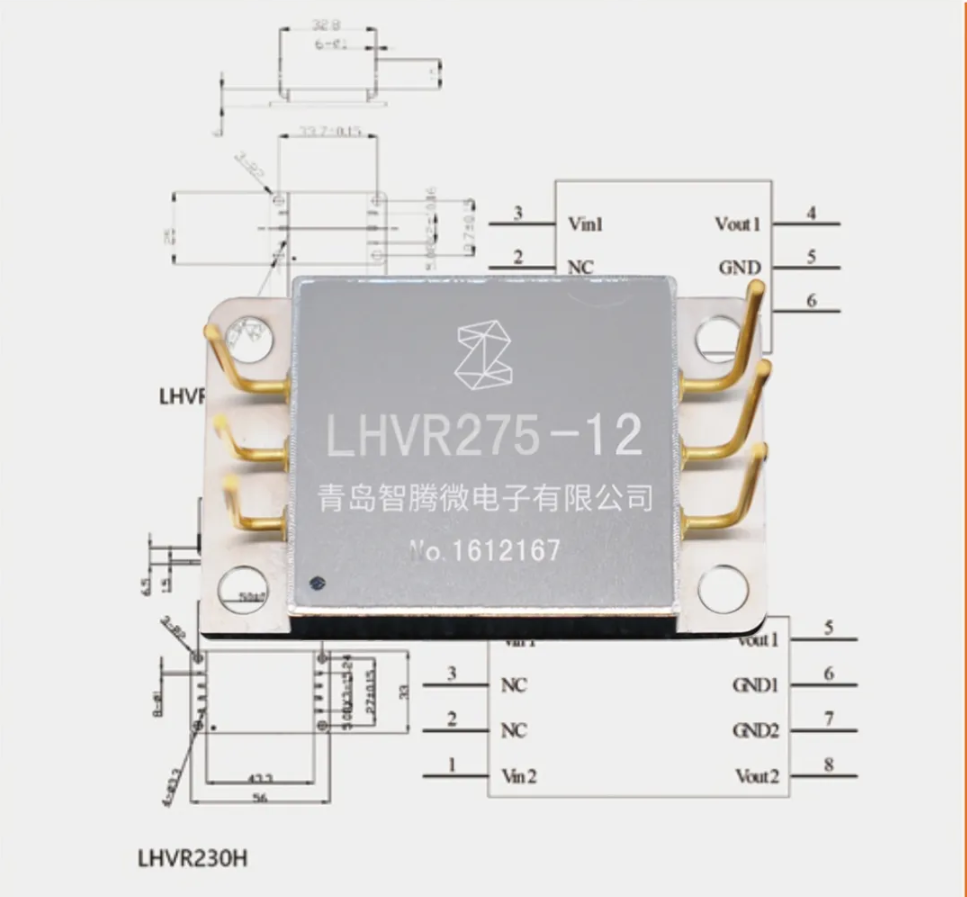

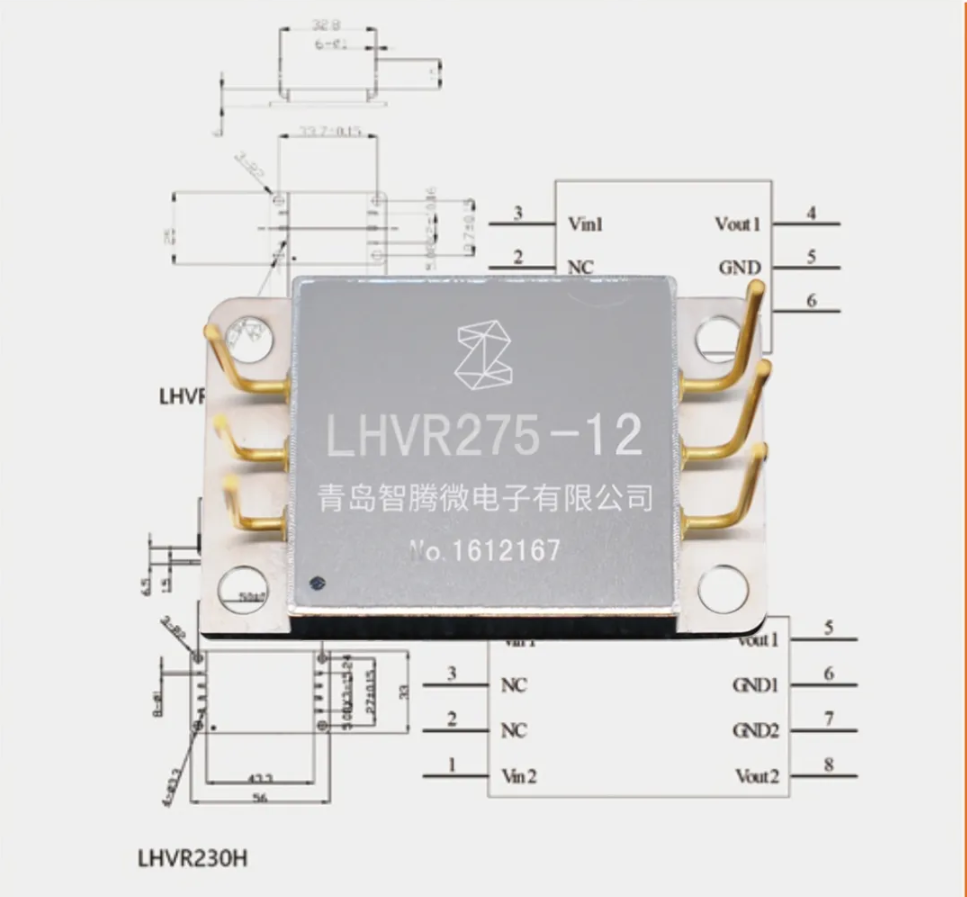

ZITN TECH independently developed the LHVR275 series of dual-channel high-temperature linear power supply modules, specifically designed for harsh environments like petroleum logging. With advantages such as high reliability, wide temperature adaptability, and strong anti-interference capabilities, it provides stable power for equipment and serves as a key technology to ensure the efficient operation of drilling systems.

Product Overview

The LHVR series is a dual-channel precision regulated power supply circuit (linear power supplies are also commonly referred to as linear regulators/voltage stabilizers) specially designed for high-temperature and wide-temperature environments. It features output stability unaffected by input voltage, load current, or ambient temperature changes. Without external filtering capacitors, the output noise remains below 1mV, and it can operate reliably for extended periods at a case temperature of 275°C.

Product Advantages

1. Ultra-High Temperature Resistance

- Suitable for 200°C logging-while-drilling (LWD) or 275°C wireline logging applications.

2. High-Reliability Design

- Gold Wire Bonding with Minimal Solder Joints: Reduces solder points and adopts gold wire bonding technology, significantly enhancing connection stability and minimizing detachment risks.

- Sintered-Sealed Flexible Connectors: Utilizes sintering and sealing technology for flexible connections, eliminating failures caused by high-temperature deformation and ensuring long-term reliability.

3. Efficient Heat Dissipation & Thermal Management

- High-Thermal-Conductivity Structure: Optimizes heat transfer paths, improving heat dissipation efficiency for core components to ensure stable operation under extreme temperatures.

4. Modular Design for Rapid Maintenance

- Plug-and-Play Modular Architecture: Supports quick on-site installation, removal, and replacement, reducing maintenance time and minimizing equipment downtime costs.